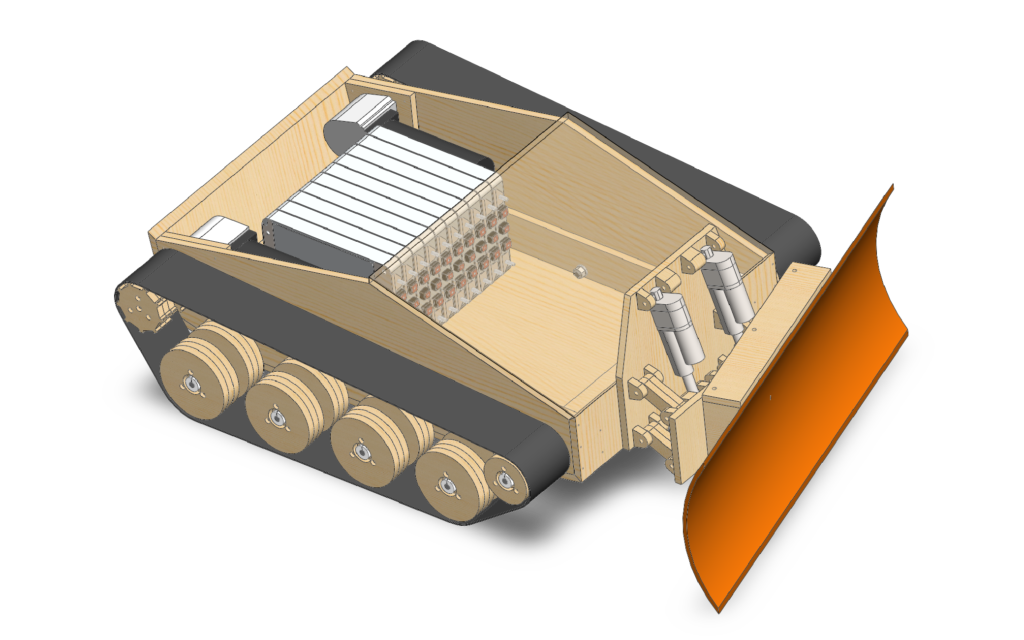

After I abandoned previous attempts at designing an RC Snow Plow, I started again with a new version, v3.0.

My previous projects: RC Snow Plow – 6×6 Wheel Drive – v1.0 and RC Snow Plow – Track Drive – v2.0 were stopped as I never had enough time to work on them and I kind of lost inspiration on those very old and bulky designs.

After we moved to a new house with a new workshop, I revisited the project and designed a new version, v3.0.

Yes, a very Cybertruck-inspired robot, but hey, why not? Right?

This time I will use a different approach.

The Design

The criteria were:

- Lithium-Ion Batteries

- Wheelchair Motors

- Plywood and 3D-printed parts

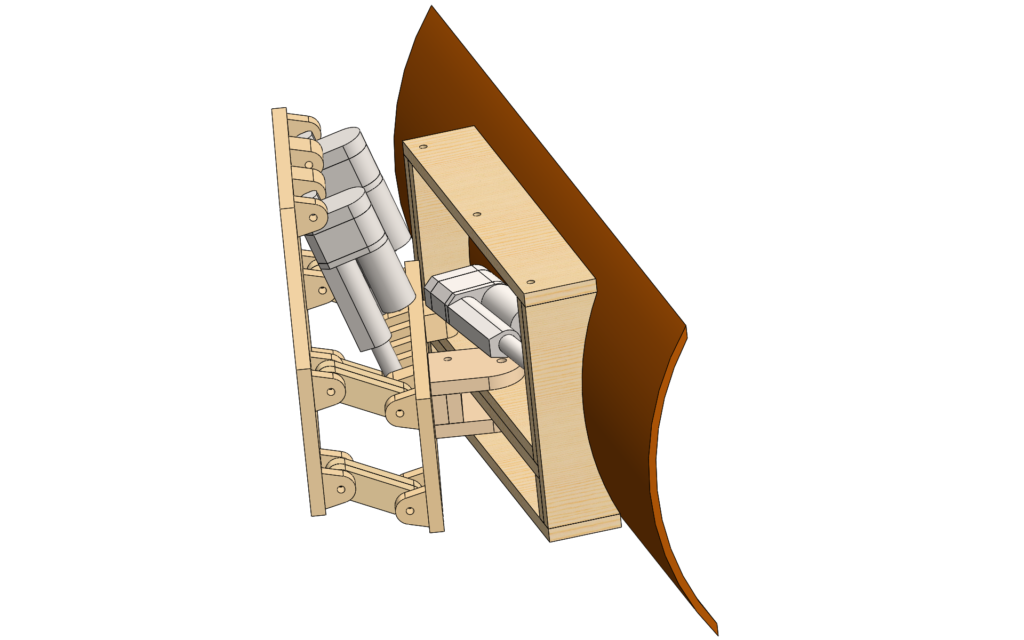

- The plow itself has to move perfectly up and down, even when rotated

- It has to fit my new CNC Router

- Option to have manual control with a seat on top for my kids

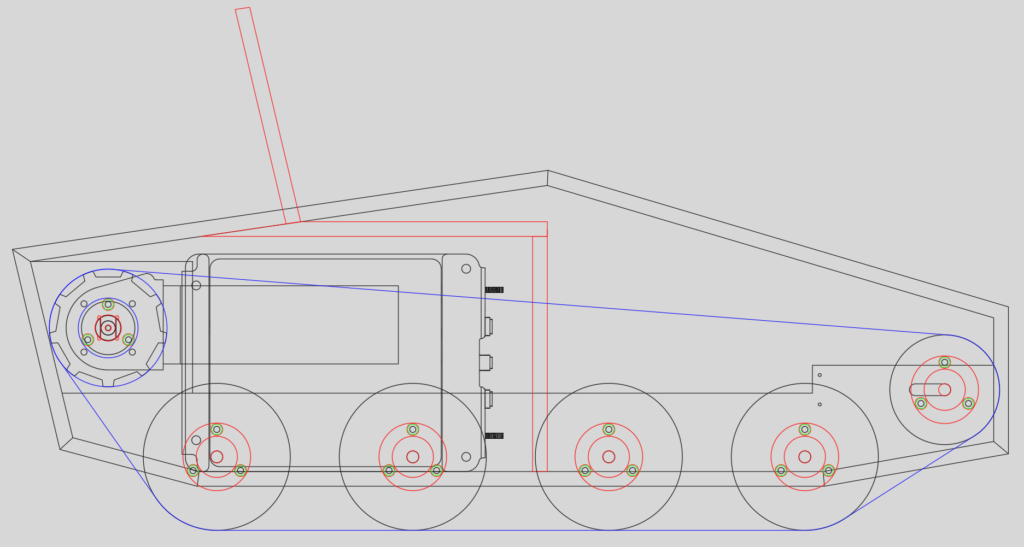

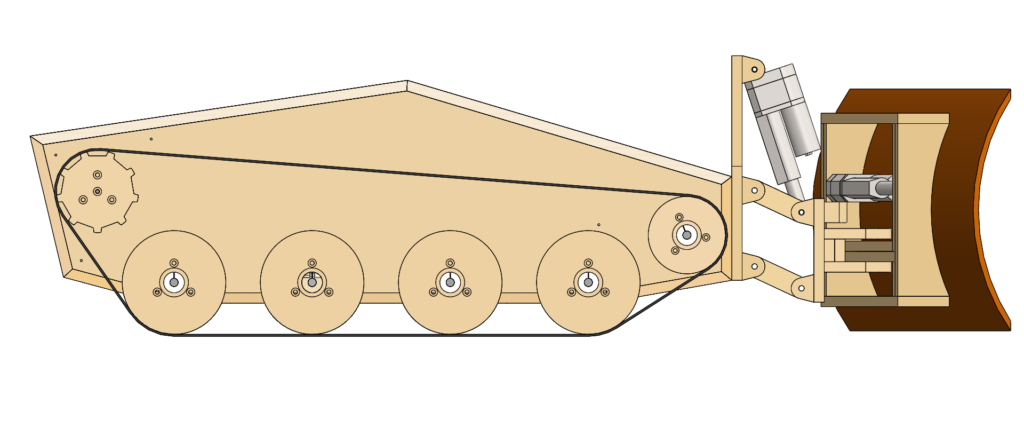

So it was time to start the design. As always, I used SolidWorks 3D CAD Design Software to make a 3D model of the new robot, but I also used AutoCAD to design the general blueprint.

I found out that it was much faster and easier to draw the blueprint and design wheels and sprockets in AutoCAD.

I am not going to show the design process. It was something I did in my spare time and stretched over a few weekends and evenings.

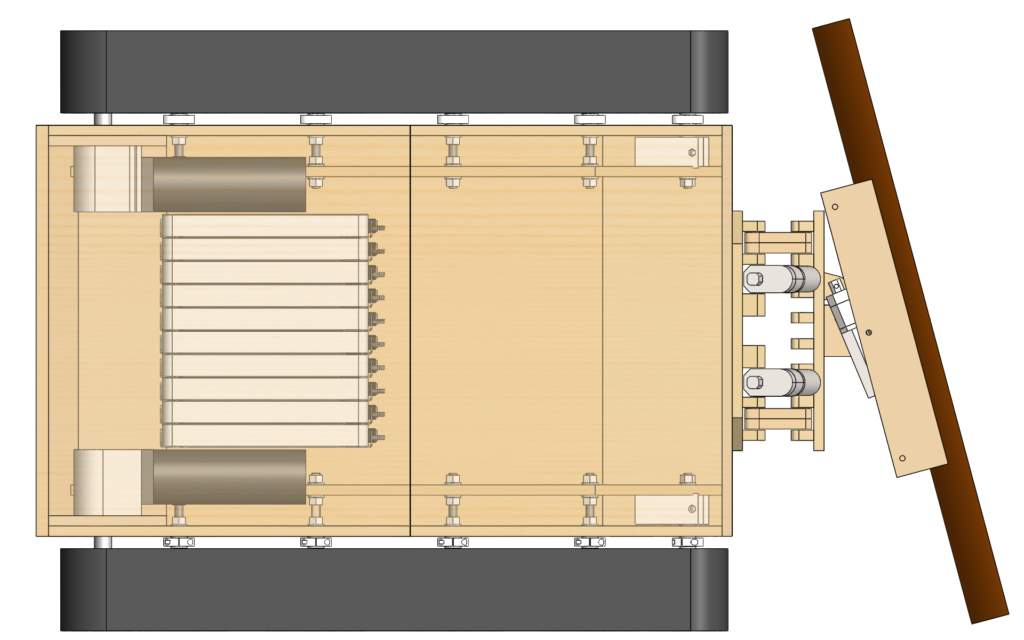

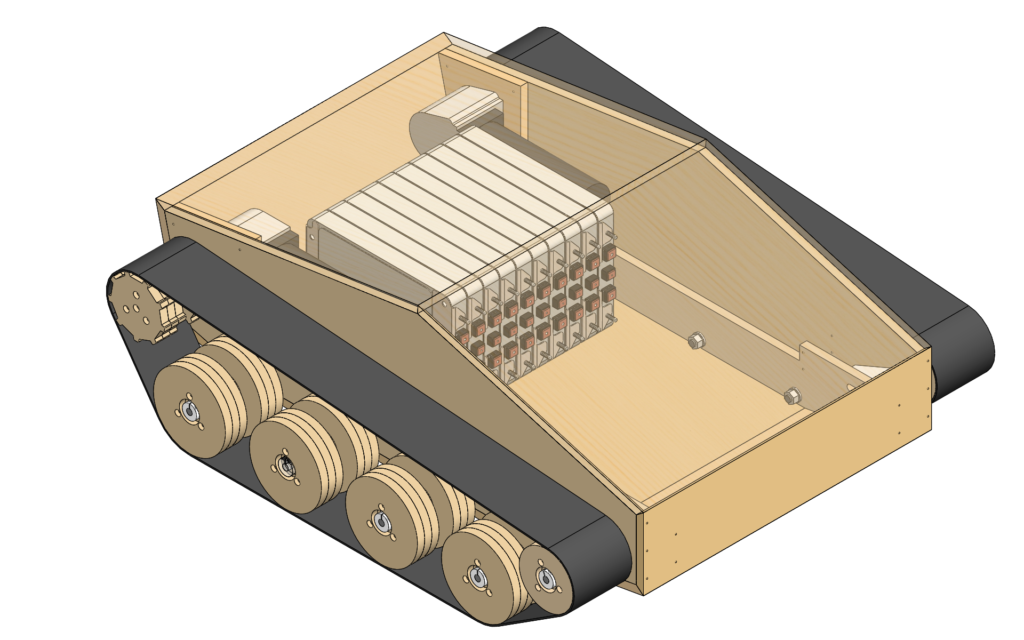

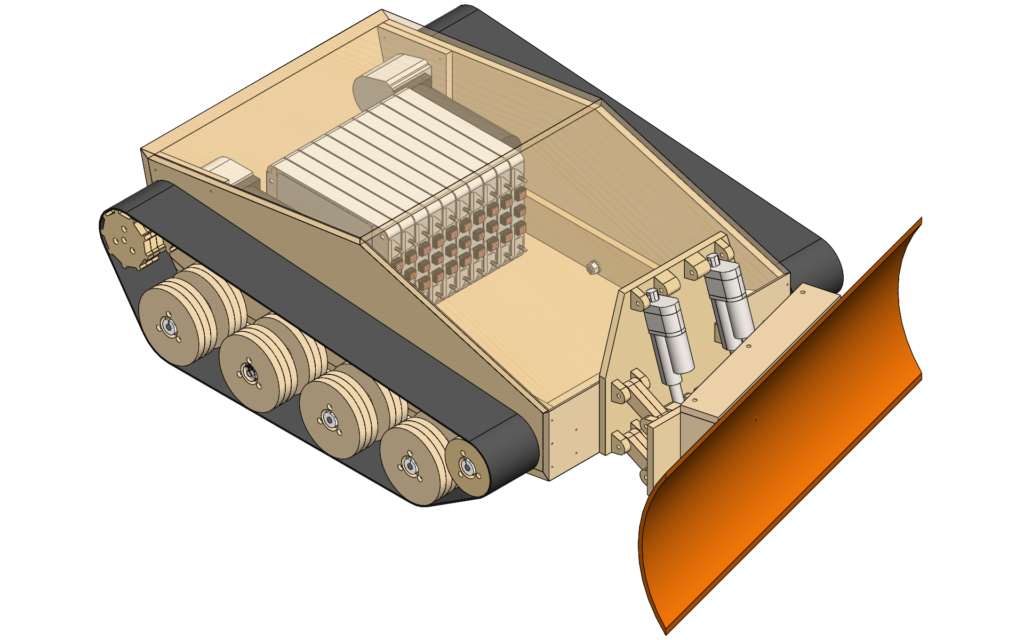

But what you can see from the last picture above, the robot features:

- 2x Wheelchair Motors

- 3x Linear Actuators

- 2×4 Drive Wheels

- 2×1 Tension Wheels

- 2×1 Drive Sprocket Wheels

- 10x Nissan Leaf Lithium-Ion battery modules

- 1x Plow made from 600mm PVC pipe

The Chassis

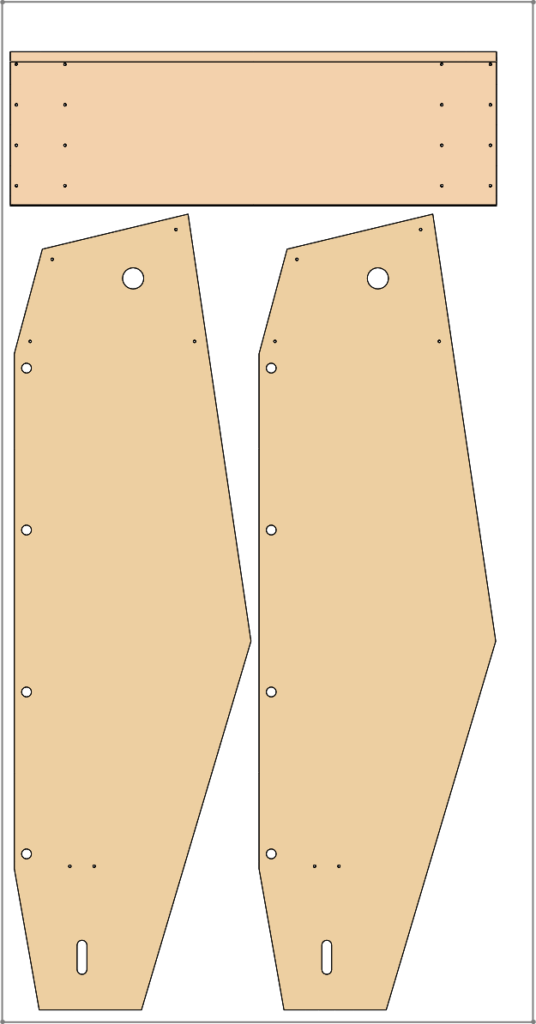

As I mentioned before the chassis was made from 15mm Plywood.

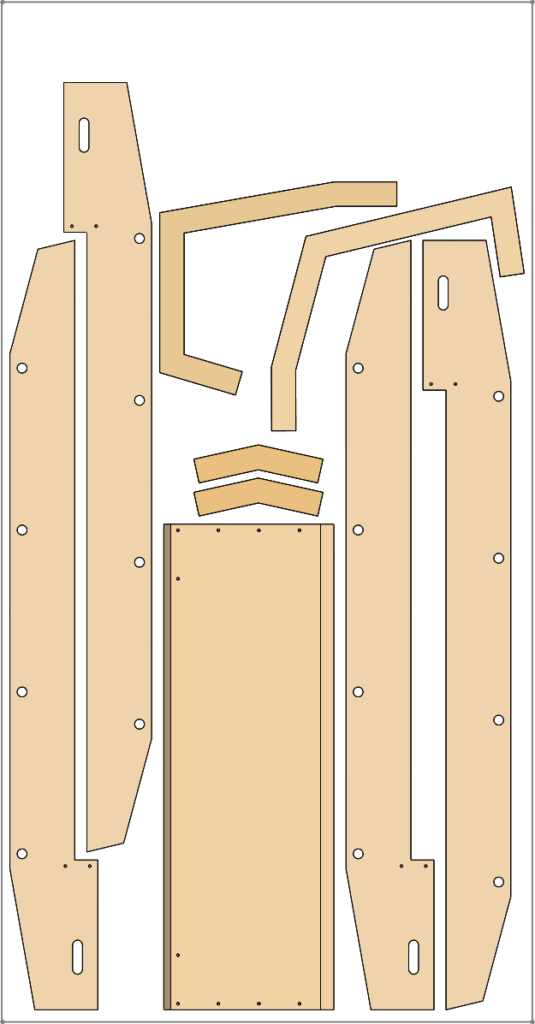

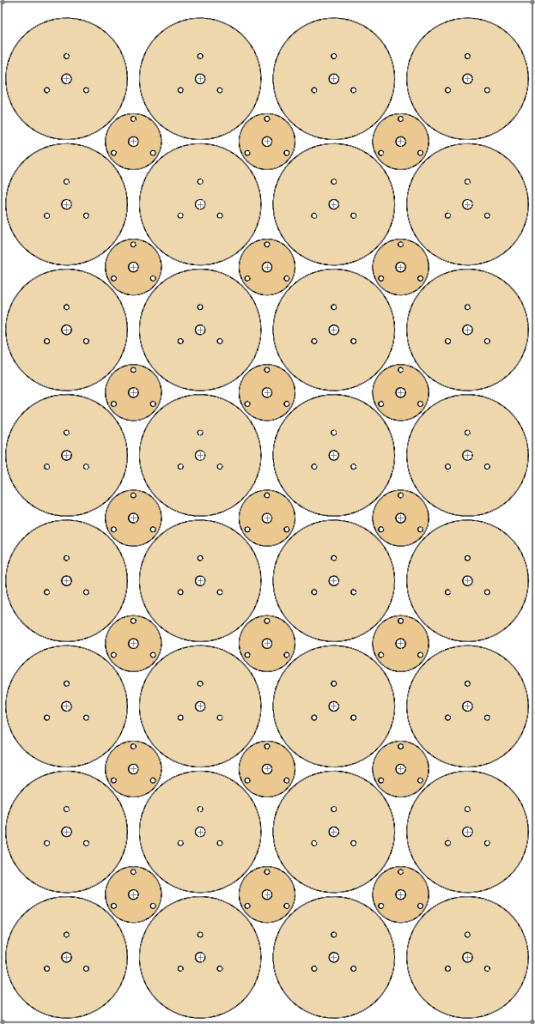

I first paced parts on cut templates in SowlidWorks and than used HSMExpress CAM software to generate toolpath for my CNC. The gray lines on the templates are my CNC’s Work Area.

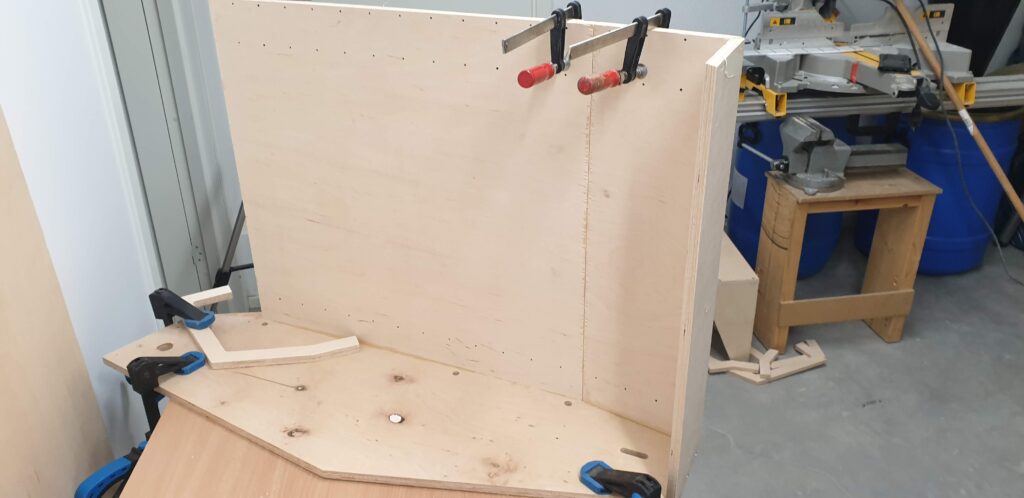

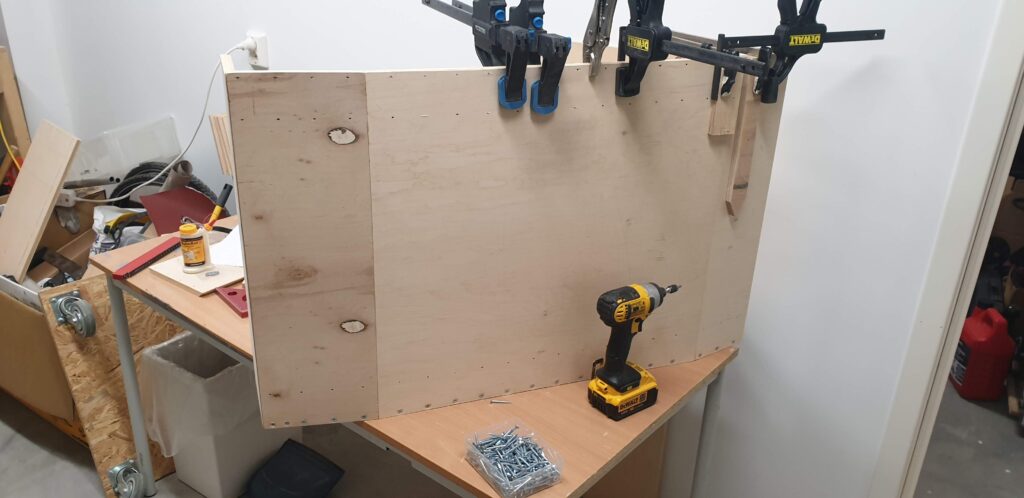

After everything was cut, I started assembling the chassis

Dry fitting

Dry fitting all elements.

The Glue Up

The chassis is done.

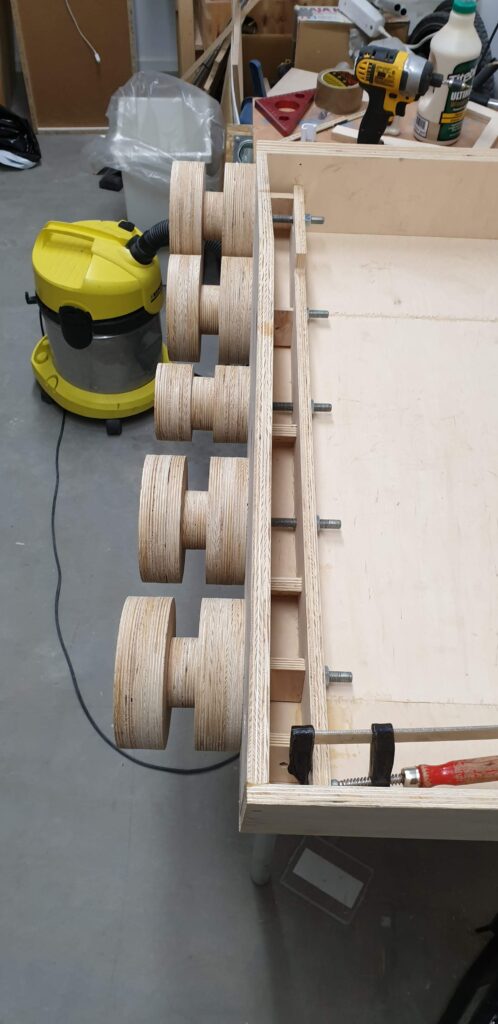

Next is gluing together the wheels from different plywood layers.

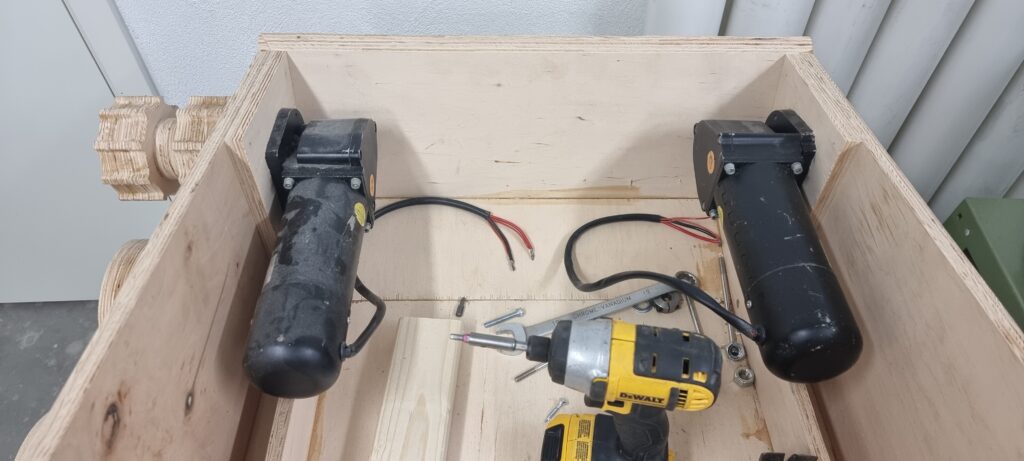

And assembling the motors

The motors are from Alpatec in the Netherlands and feature 10.8A@24V, 116rpm, and 10.3Nm of torque.

This is starting to look like an RC robot.