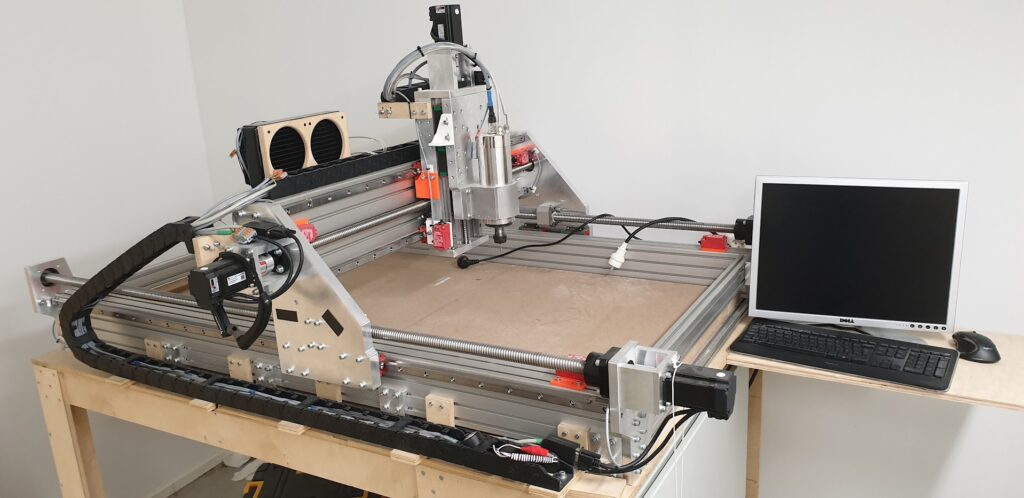

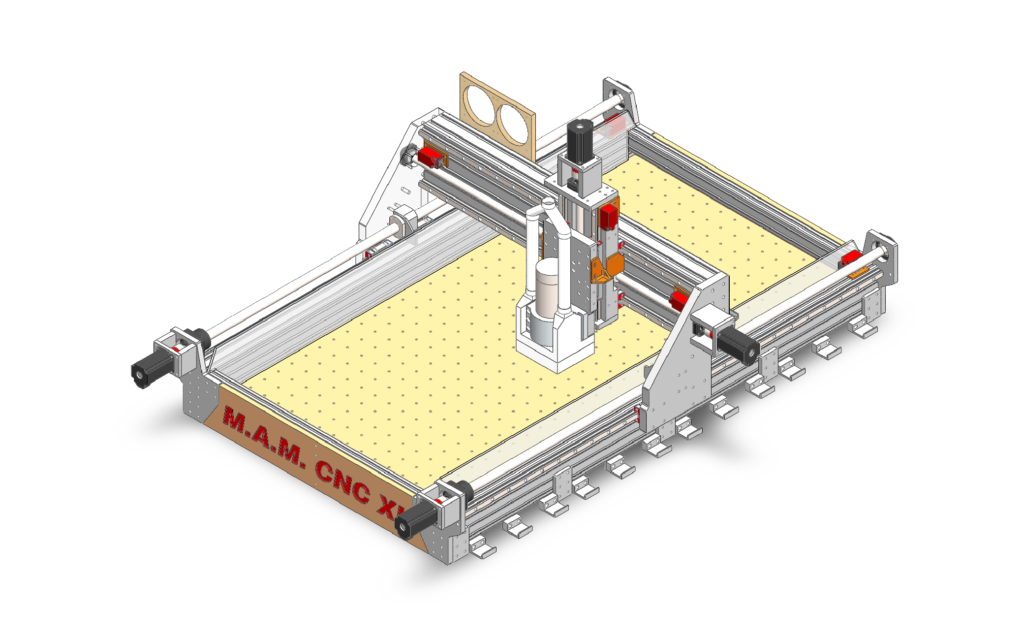

The new CNC router features a 1250x650x150 work surface, an all-aluminum design, a water-cooled spindle, and an industrial-grade CNC controller and VFD.

From the beginning of my CNC journey, I helped design and build many CNC routers for my friends, from plasma cutters with a 2400x1200x100mm work area to desktop CNC routers.

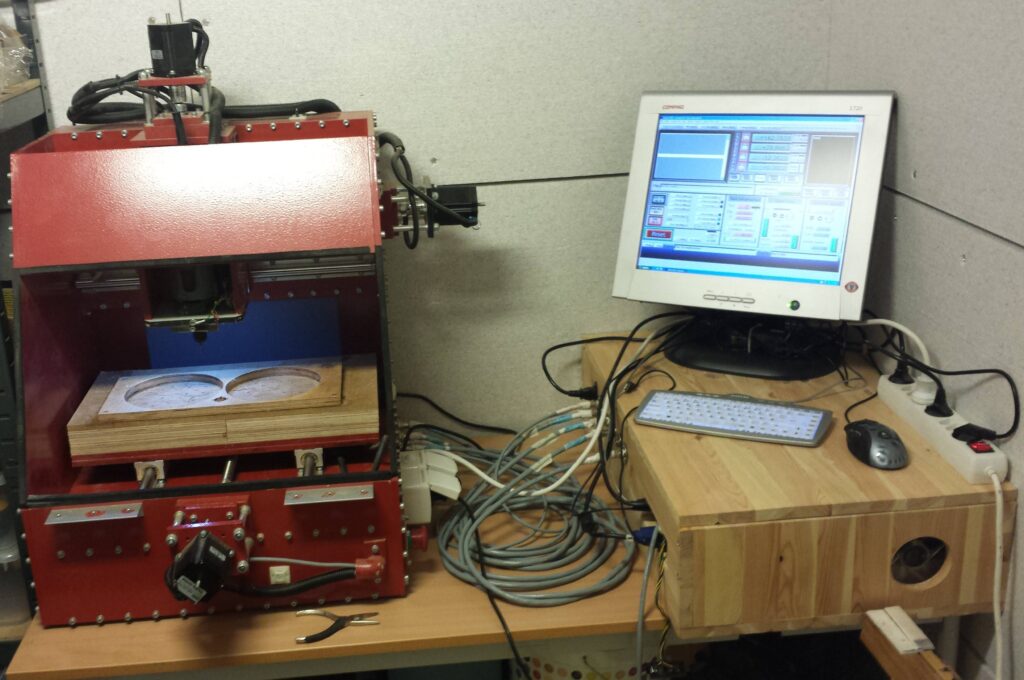

My last CNC router was a little desktop machine with a small work area that could fit nicely inside a small storage room in my old apartment.

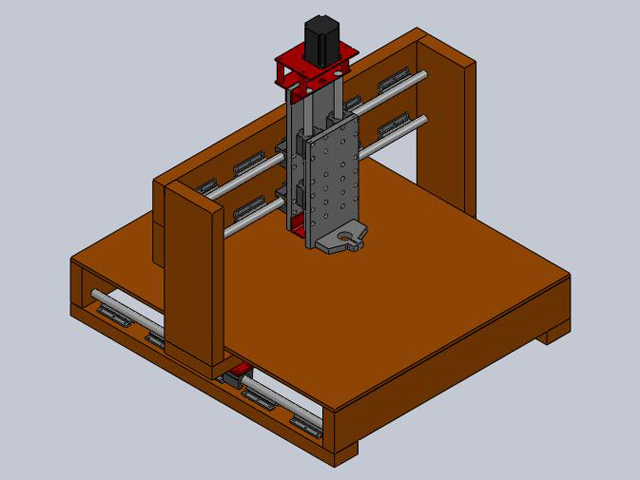

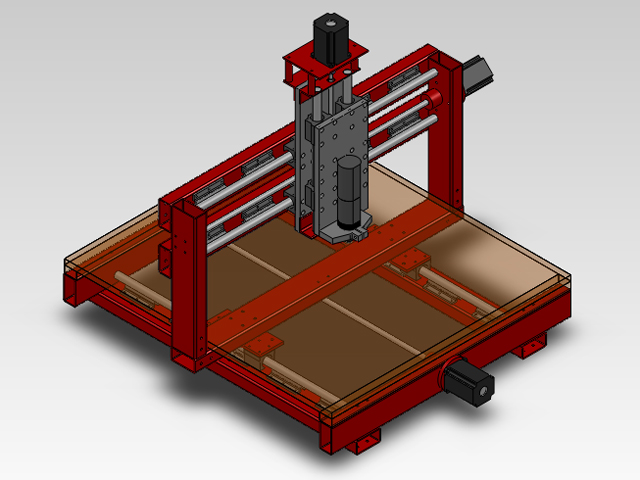

Some of the earlier projects:

All those projects were small, cheap CNC routers with small work areas and few possibilities.

My last CNC was made from composite materials and had a small 1050W router motor.

It was time to design a new one. This time I wanted something bigger, better, stiffer, and much more powerful.

My key criteria were:

- Work Area 1250x650x150mm

- Aluminum Extrusion Profiles

- Ballscrews

- Closed Loop Stepper Motors with Encoder Feedback

- 2.2kW Water-Cooled Spindle Motor with VFD

- Better Controller

- Metal Case for Electronics

The design of this took me some time, as it is my hobby and I only worked on it in my spare time.

I used SolidWorks to design this machine.

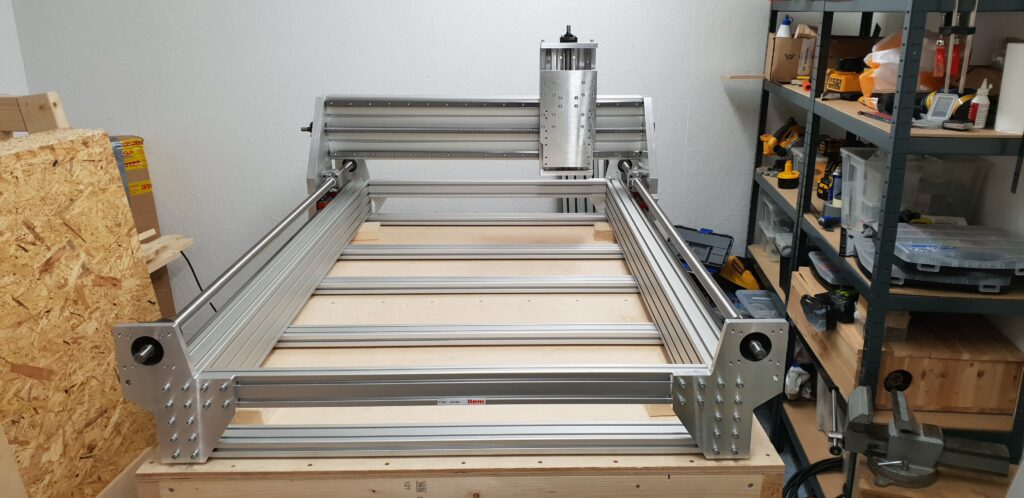

The finished project was like this:

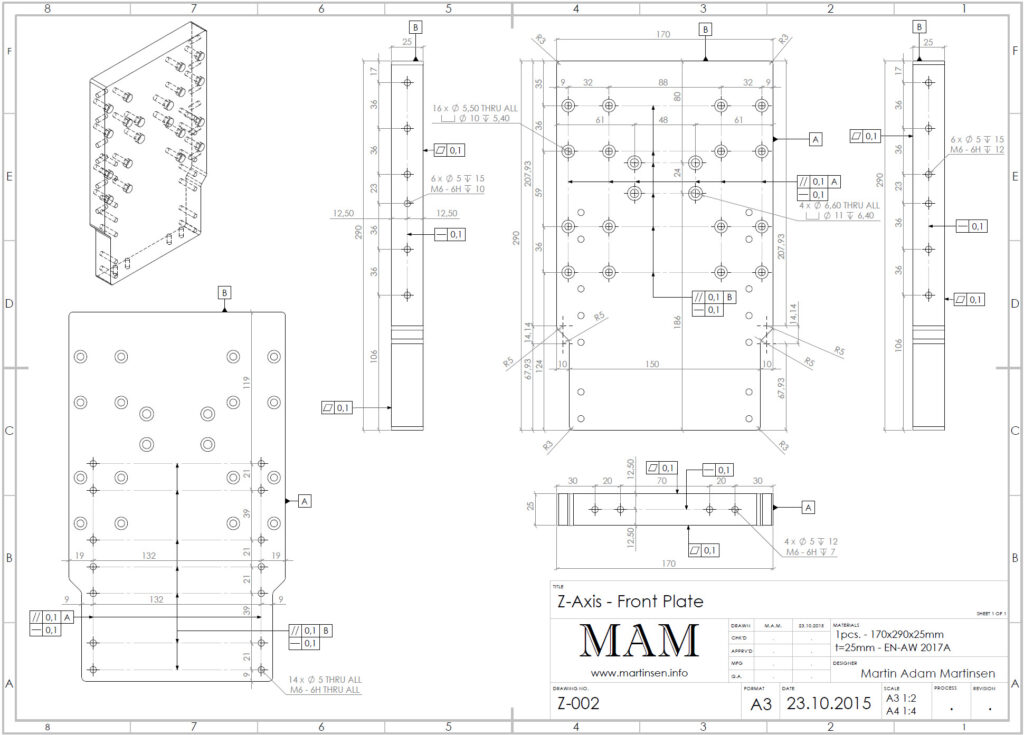

I first made production drawings of aluminum parts, which I sent to China for production.

Oh, BTW, if you look at the drawing, the parts I designed were not using 6061 aluminum but 2017A, which is an aerospace-grade aluminum alloy.

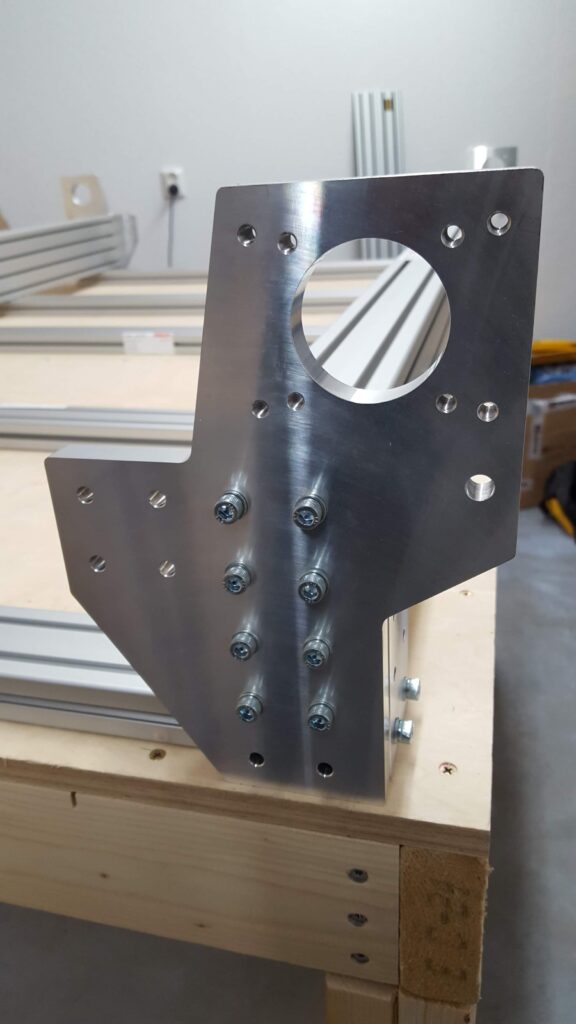

The accuracy and quality the Chinese manufacturer achieved were amazing.

The picture tells everything.

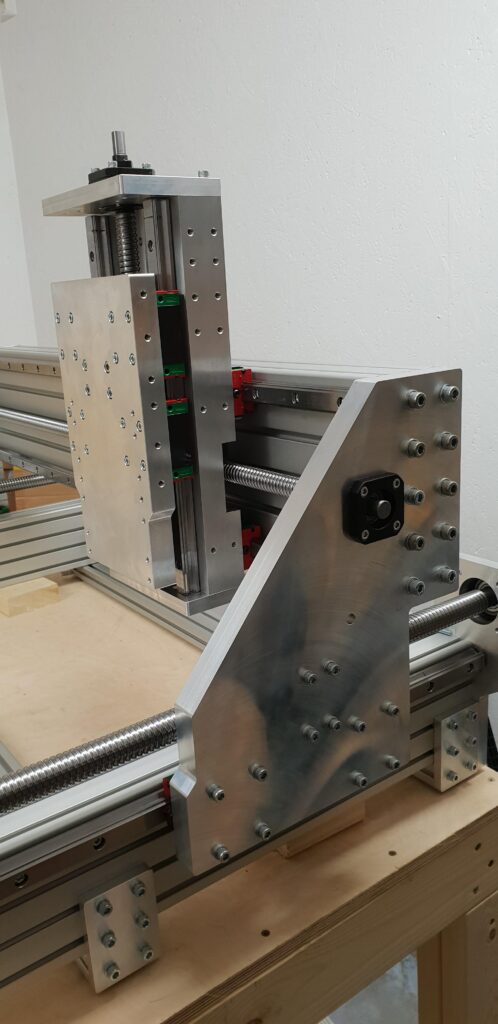

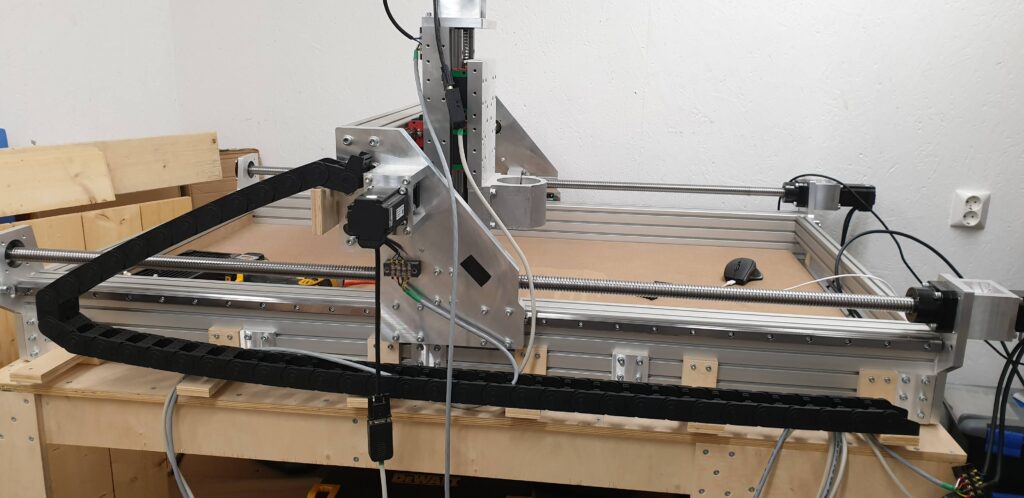

After receiving all the necessary parts, I started to assemble my new CNC router.

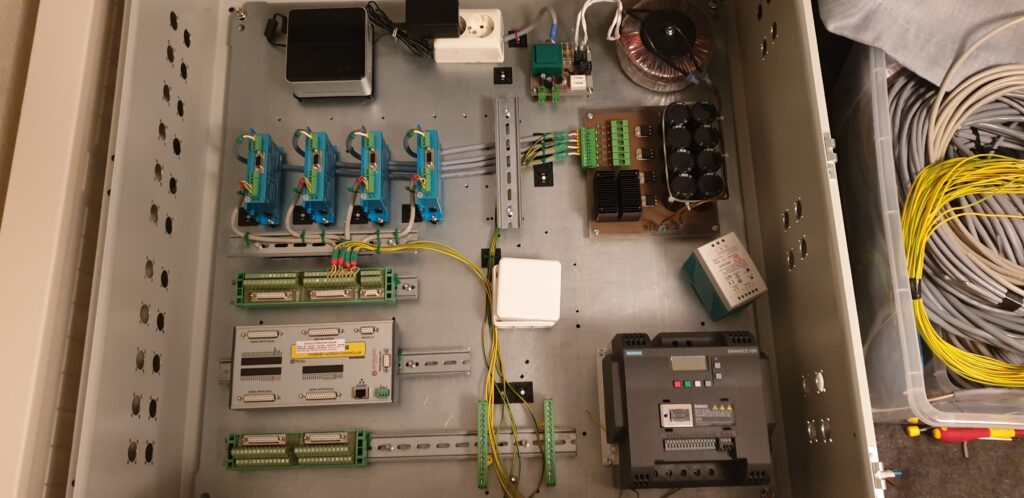

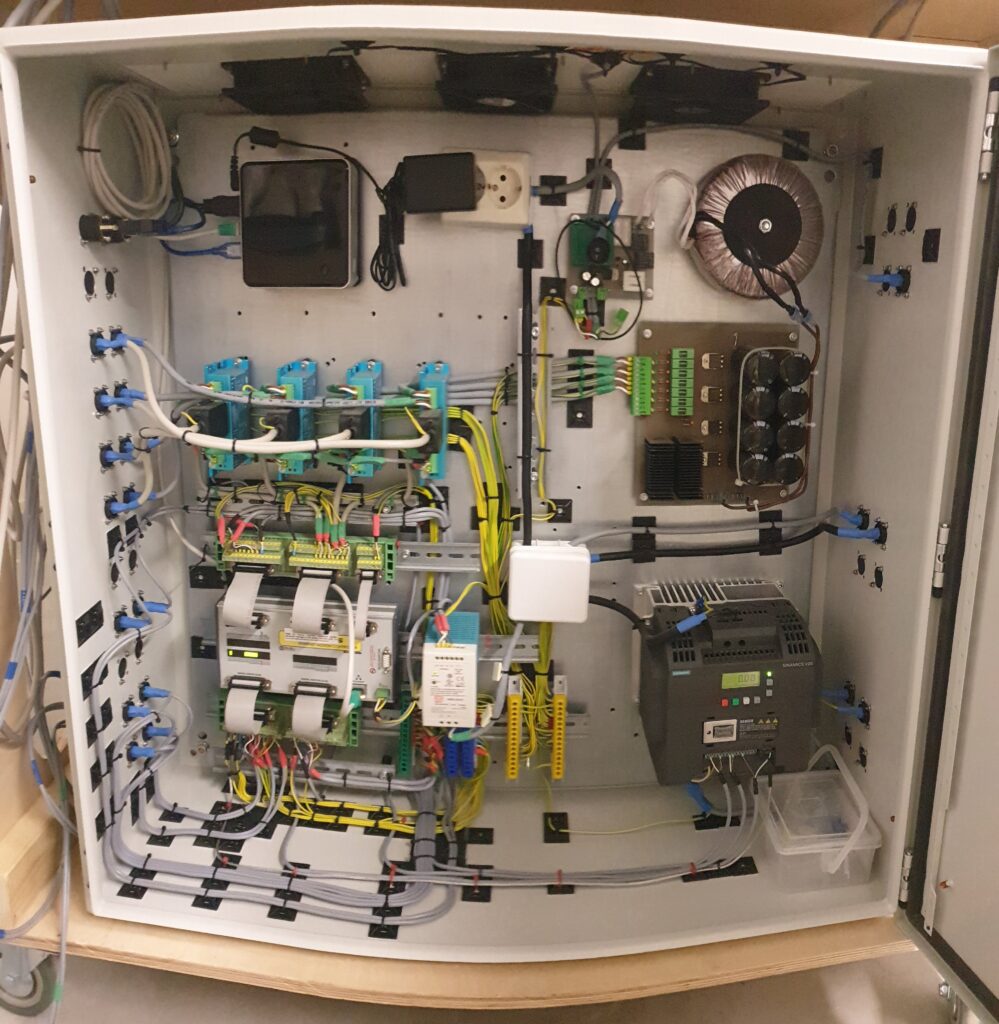

When the mechanics were almost done, it was time for the electronics.

I used a metal case with a size of 800x800x300mm.

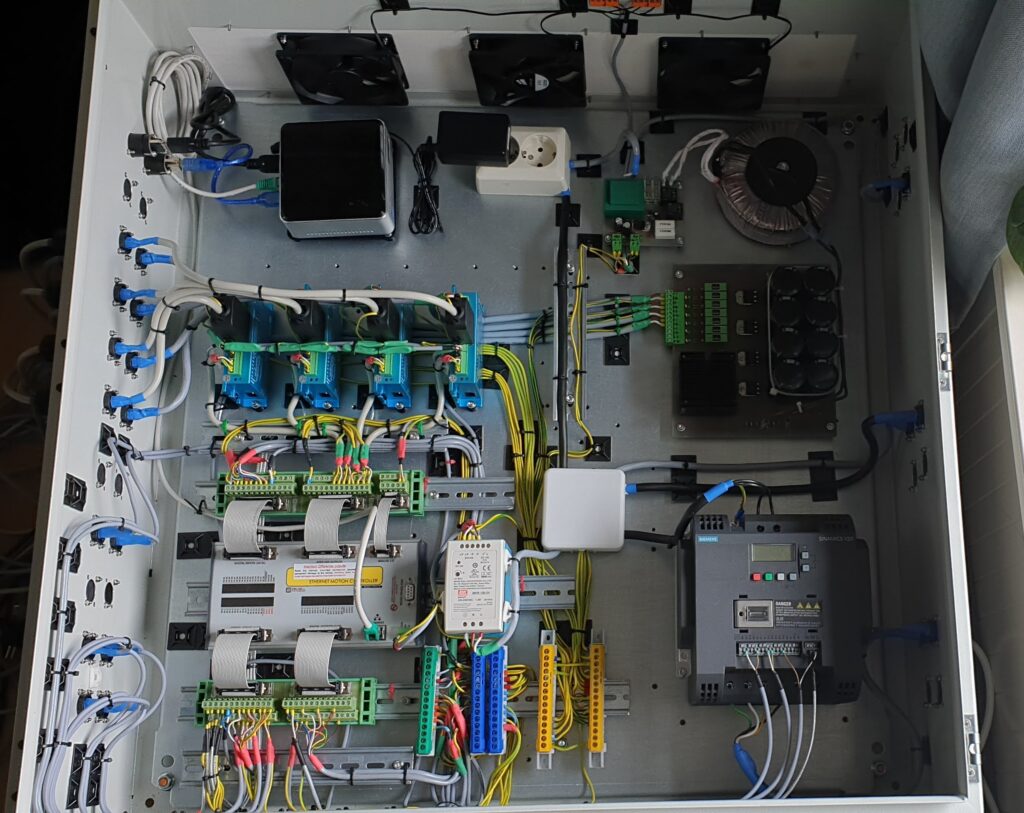

This is how the finished electronics case looks. It took me 80-100 hours to finish, but I am very happy with the result.

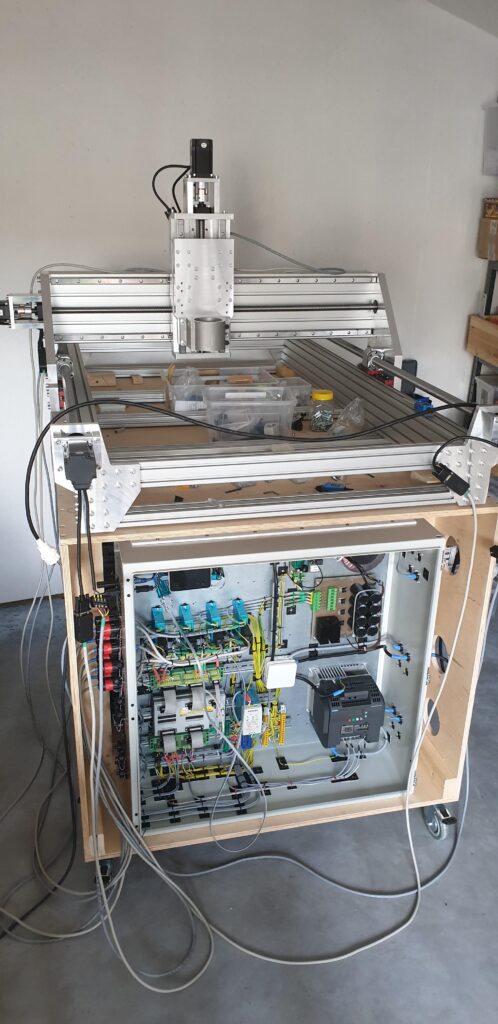

Here is how the case fits inside the table.

This was a very fun project where I could use many of my 3D design & modeling, soldering, electronics design & configuration skills.

The new CNC router looks awesome and works fantastic.