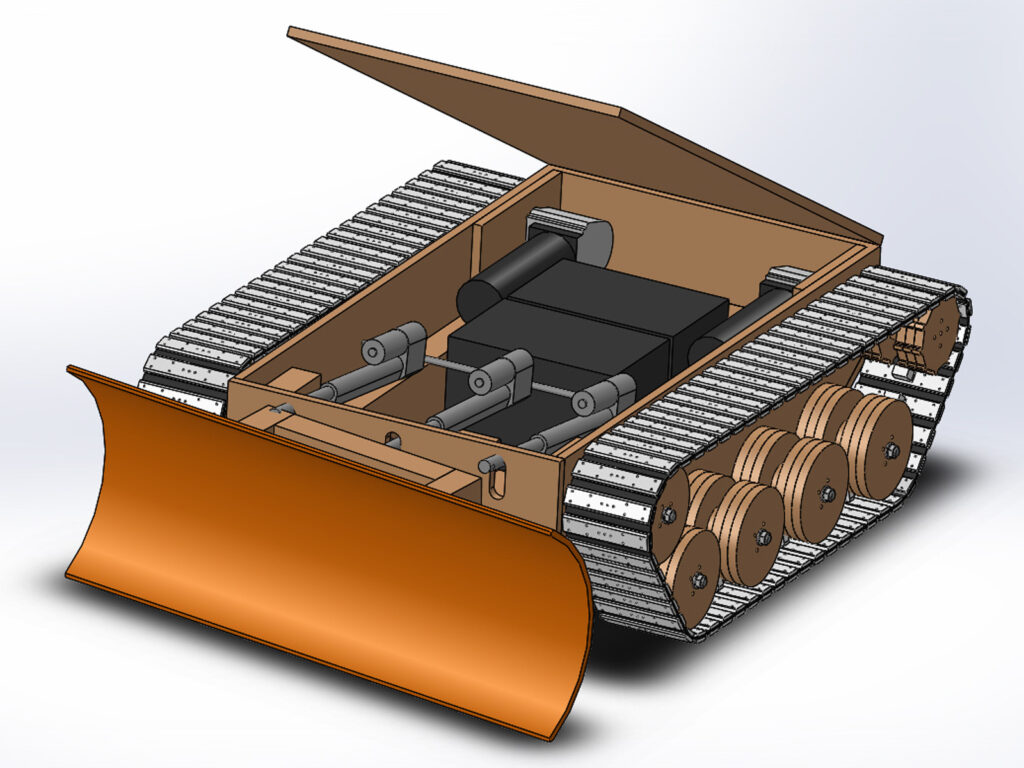

After my previous prototype of RC Snow Plow – 6×6 Wheel Drive – v1.0, I decided to simplify the design by using tracks instead of wheels. There are no chains or timing belts between the motors and the drive wheels. This reduces the complexity of the entire drive system. The tracks may sound very difficult to make, but they aren’t.

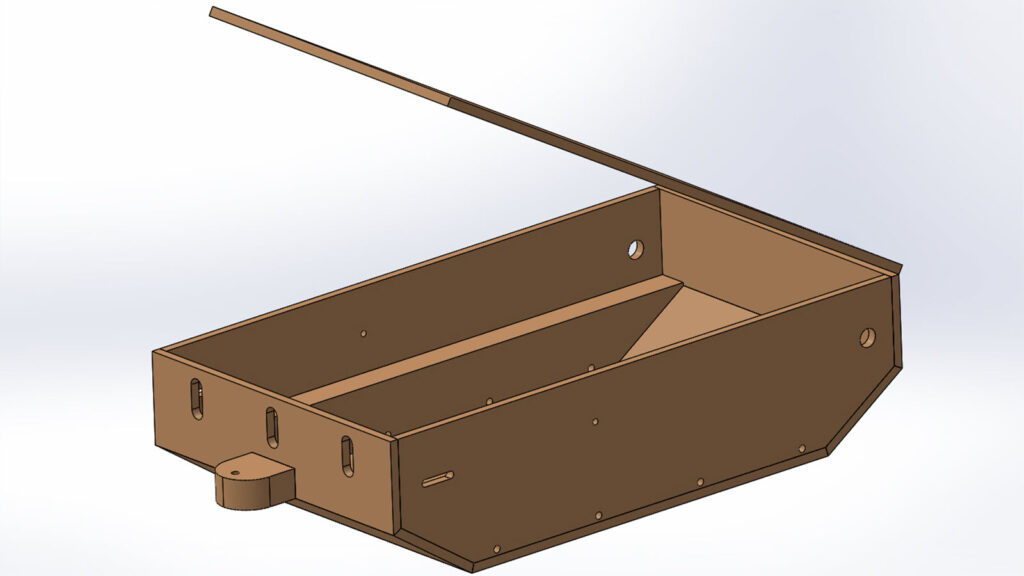

The Chassis

First, I designed a chassis out of 15mm plywood. The bottom part of the chassis is profiled like a tank so it can move easier in deep snow.

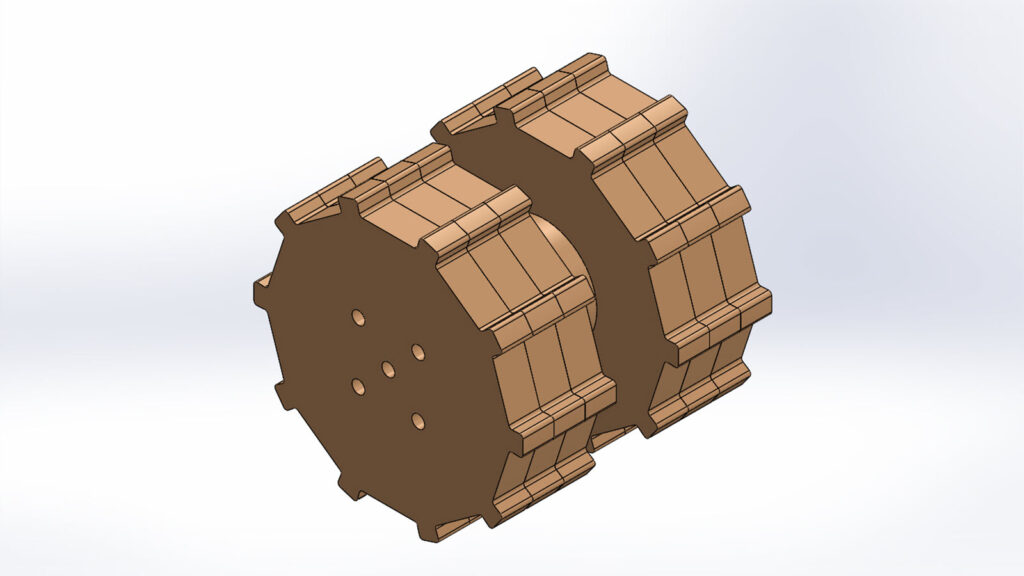

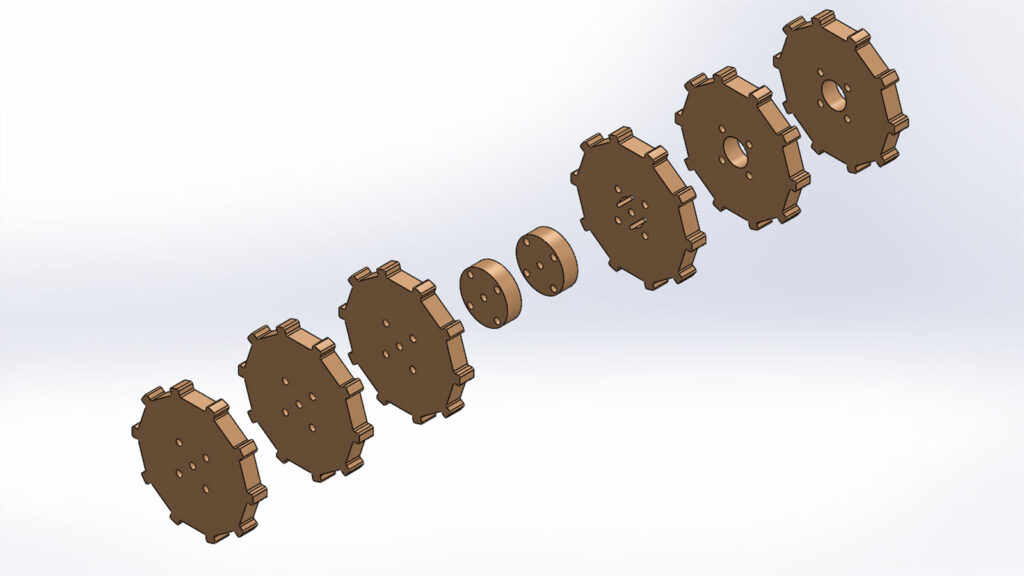

The Wheels

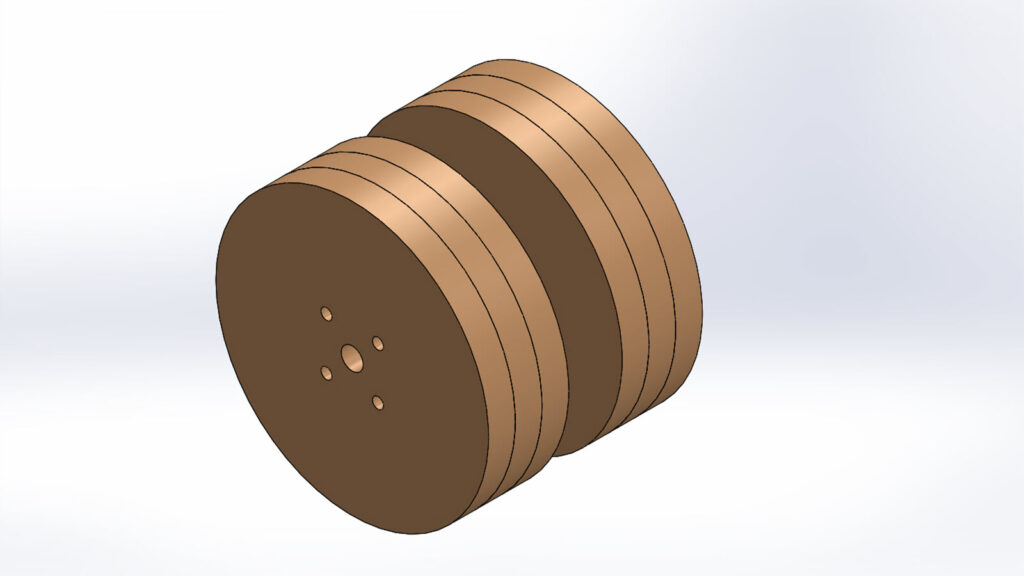

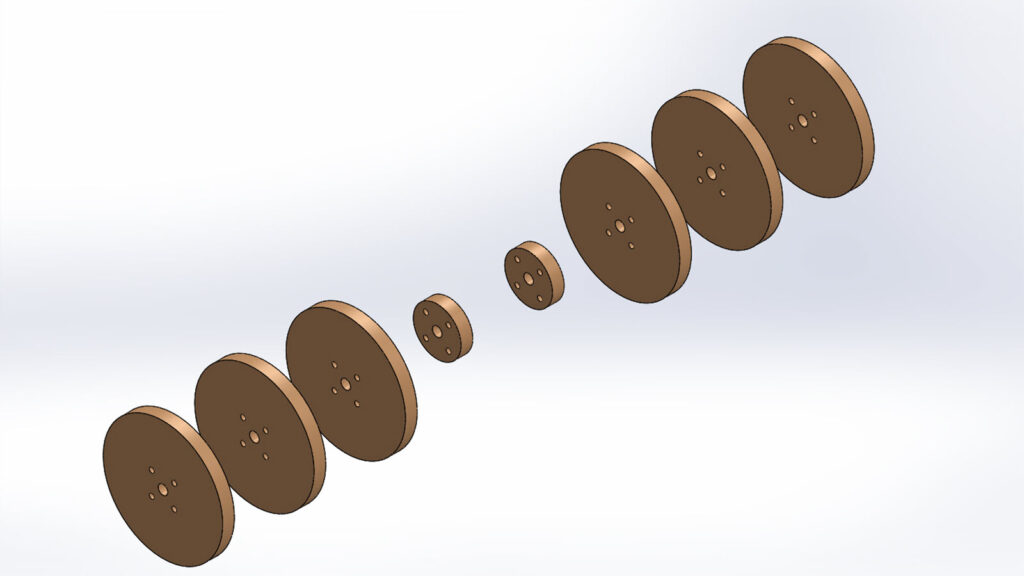

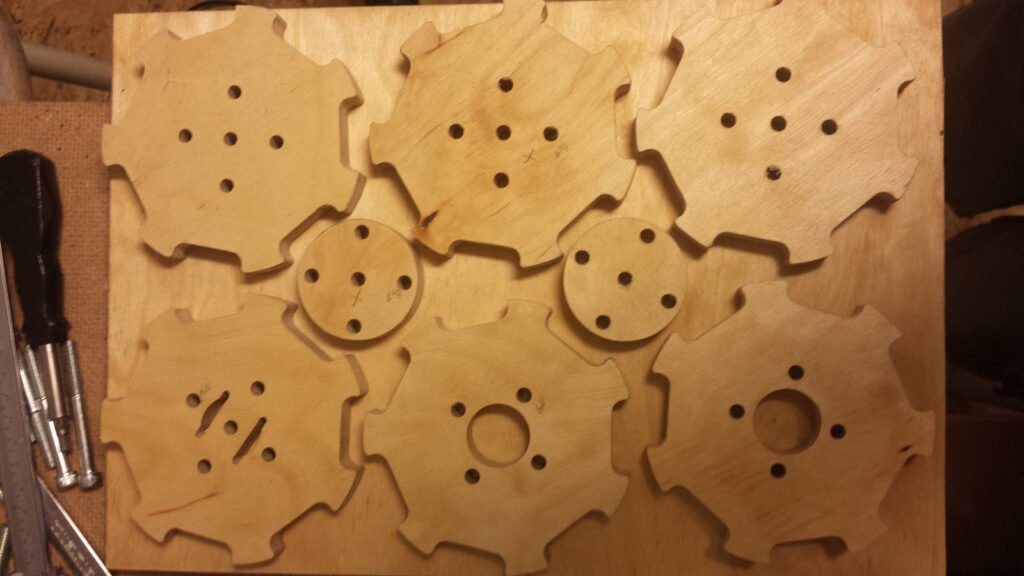

The next parts are the wheels:

- Drive sprocket wheels (ø120mm)

- Main wheels (ø150mm)

- Tension wheels (ø120mm)

All wheels are made from 15mm plywood.

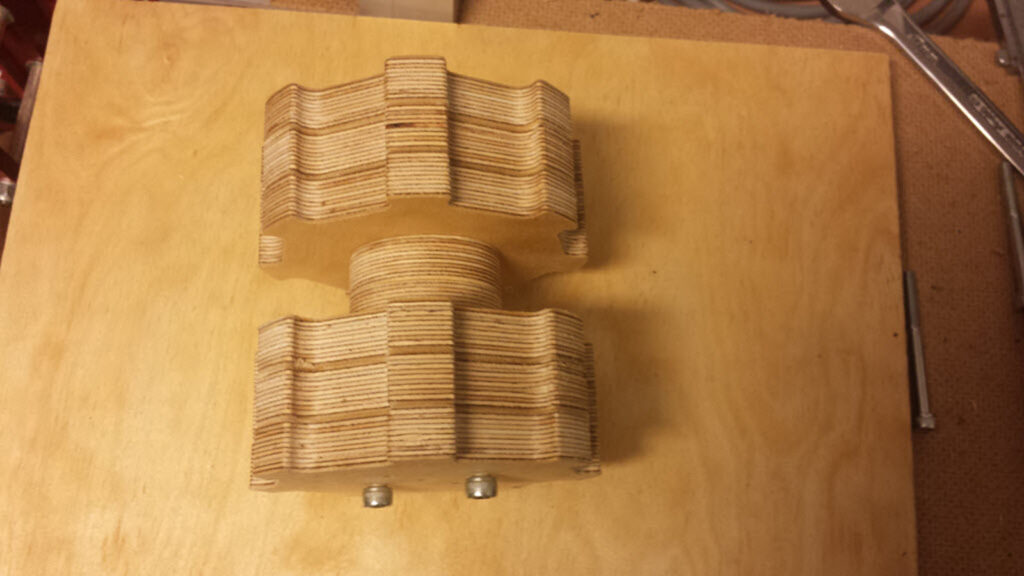

The drive wheels are mounted directly onto the wheelchair motor shaft. The spacer between the inner and outer layers of the wheels holds track tools, so the track doesn’t fall off. Main and tension wheels are made with the same principle, but they run on the shaft. I have seen solutions where plywood wheels were running on the shaft without any bearings, so I will try and see how it works.

All wheel parts are screwed and glued together.

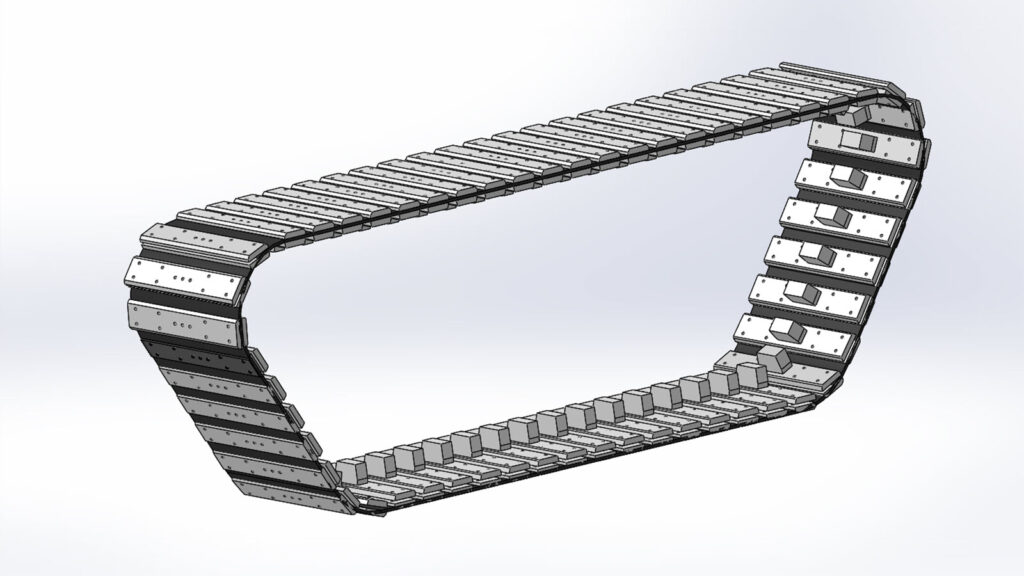

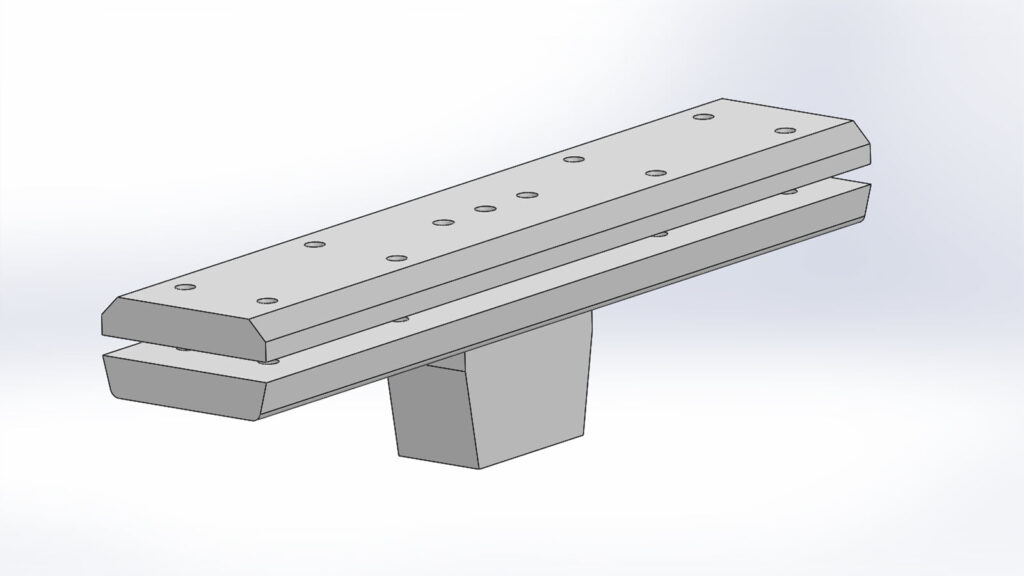

Tracks and Pads

The tracks are made from a 3mm thick treadmill belt, and the pads are made out of 6mm plywood.

The teeth are joined with dowels and glue to the pads. I am going to use M3 bolts to screw the pads to the belt.

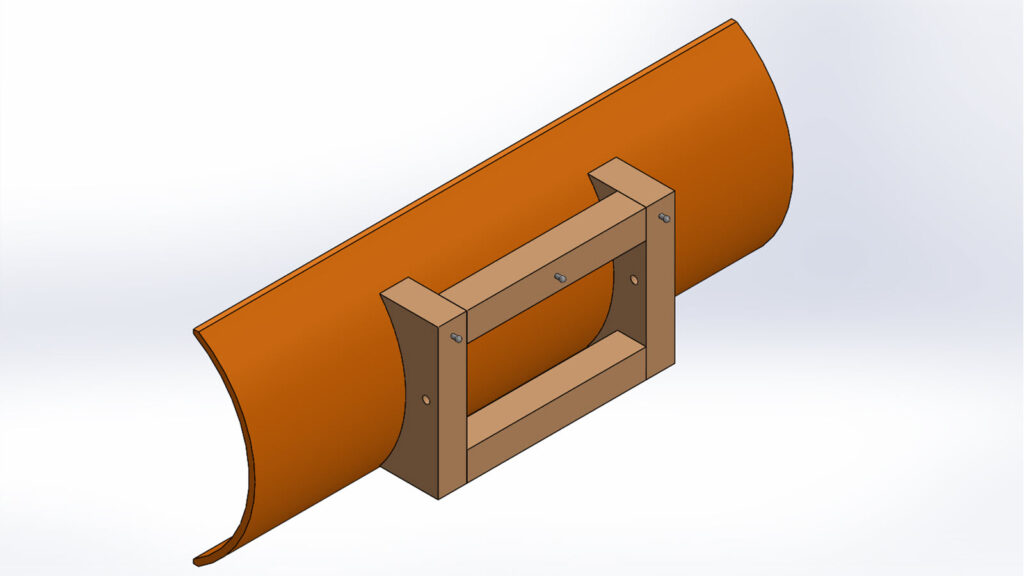

The Plow

The plow is made out of a 600mm PVC sewage pipe, cut in half. The mounting bracket is made out of regular wood, shaped to the pipe’s curvature.

Test cuts of the wheels

After I made my prototype with the wheels (RC Snow Plow – 6×6 Wheel Drive – v1.0), I tried to cut the main and drive wheels on my old CNC before I sold it.

The results are as expected, and now I know that the new design will work! It will take me some time before I make this new prototype. It is because my new CNC router is still in the box, and it will take a few months before I can assemble it. Be patient.